Configure to Order with DriveWorks

Let me lay out a really common workflow for you. A customer calls up someone on your sales team, asking for a quote. Sales are excited and, of course, provide a rough estimate, before talking to engineering. The happy customer cuts a purchase order and now engineering must design something to fit the specifications that sales didn’t validate before the sale. Now nobody knows what’s going on and both engineering and sales are in a tough spot. Wouldn’t it be great if we could do all of that in a single system? Better yet, what if we could turn our sales process into a true configure to order process?

An Integrated System for Engineering and Manufacturing

The goal of a full system is to provide you with a single location to configure a solution, while also providing immediate pricing and a method to turn that into a quote. By nature, a system like this is going to touch multiple groups and needs multiple layers of validation. However, using a full solution helps prevent situations like the one I laid out at the top.

So which systems will this talk to? Well first, a configuration tool needs to have a tie into engineering and manufacturing. Let’s talk about this as it relates to one of my favorite tools, DriveWorks. DriveWorks is an automation solution that links directly to your SOLIDWORKS models. This means that whoever uses DriveWorks can get immediate engineering feedback, without having to rope in a designer. It also means you can get models and drawings with just a few clicks. But we don’t want to stop at configuration. We also need to price out a project. For this, we turn to DriveWorks’s integration with systems beyond SOLIDWORKS.

Tying Into Sales

Every business is different in how they create pricing. Some use simple pricing sheets, others use tools like QuickBooks, and even ERP comes into play. Whatever the system, sales needs accurate pricing to sell our products. Let’s think about how sales get the pricing right now in the scenario at the top. Currently, sales should work with engineering to price out a job. However, when we’re in a rush, we often skip steps that we think we can do just as well. The problem is that we can’t always do that with perfect accuracy.

This is where it benefits you to have an integrated automation solution. We’ve already talked about creating a system where engineers configure models on the fly. Now, we put something like that on a website and tie in pricing so that anybody we want can get an accurate price along with an accurate model. Once again, let’s take a look at DriveWorks.

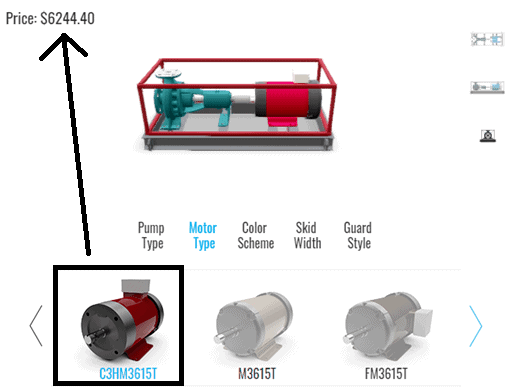

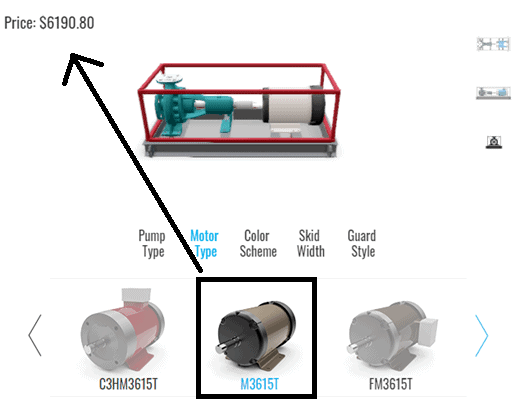

I made each of these models using the same configurator and notice that the price of the system changed based on the selected motor type. It’s a simple swap, but these changes may not always be standard. This is what a full solution does for engineering and sales. Now we can get an accurate price to our customers instantly, while also knowing that we can manufacture the selections we’ve made without any problems.

How Can Configure to Order Benefit You?

Providing accurate pricing and engineering specifications are two major components of any business. If you do one well while the other lacks, we don’t have a very sound solution in place. What makes a configurator, complete with pricing, such a powerful tool is our team can provide pricing for manufacturable solutions on the fly. This frees up time for your engineers to focus on value-add work and allows sales to engage with more customers than ever before.

Let’s Start Using Configure to Order!

The beauty of an integrated system is that you can start anywhere. Do you have a design that you think could benefit from some automation? In that case, check out DriveWorksXpress, a free automation tool that’s incorporated into every seat of SOLIDWORKS! Or maybe you have a parts catalog and just want to see what’s possible. If that sounds like you, check out the Building Components or Industrial Components demonstration on the DriveWorks Live website.

And if you don’t know where to start, CATI is always here to guide you in the best direction for what you need. We talk about these tools day-in and day-out and have years of experience finding the best fit for whatever tool will help you do your job the best.

Nick Sweeney

Applications Engineer

Computer Aided Technology

Blog

Blog