Stratasys 3D Printing: Discovering Your 3D Printer’s Capabilities – Part 1

Discovering Your 3D Printer’s Capabilities – Part 1

This is the first of a series on ideas to understand the capabilities and limitations of your 3D Printer. When you know what your machine can achieve it can be applied to significantly aid your part design as well as throughput and quality.

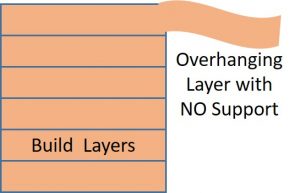

Regardless of the 3D printer you are using, it is drawing a 2D image in multiple layers to create the 3rd dimension. With this in mind, most printers will require some kind of support or brace to prevent overhanging layers on top of a previous layer from collapsing. Some machines, typically powder based machines, will use the unused material itself as a support for the next layer.

Some designs can be ‘self-supporting’ and not require a support system. This ‘self-supporting’ design is dependent on three variables; technology, material and layer thickness. For example, because Polyjet is printing drops in micron layers every down-facing surface must be supported, otherwise gravity will cause it to fall. But other technologies such as FDM (Fused Deposition Modeling) can have enough strength to build a layer that slightly overhangs the previous layer to produce an angle.

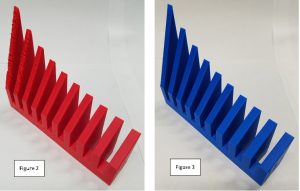

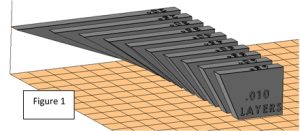

Creating a part with a series of angles (20o – 65o at 5o increments), positioning it as shown in Figure 1 and editing the parameters to build with no supports will easily show the maximum unsupported angle that can be built for that particular technology, material and layer thickness. The STL file shown here is available upon request from Mark.Abshire@cati.com.

The part shown in Figure 2 was built with FDM using ABS material at .010 inch layers. Notice that even with no support, the part built without a crash, but some surfaces on the shallow angles are ‘sagging’ and are not acceptable without supports. This gives you an idea of what angles you can incorporate in your design to minimize support build time and cost.

However, what if we change just 1 of the 3 variables (Technology, Material and Layer Thickness)? The same part shown in Figure 3 was built with FDM using ABS material at .007 inch layers. Changing just 1 variable of building at .007, instead of .010 inch layers, we can produce a good surfaces even on the shallow angles. This is because with smaller layers, the overhang is not as great as with thicker layers.

In part 2 of this ‘Discovering your 3D Printer’s Capabilities’ series we will discuss building horizontal holes in a part.

Computer Aided Technologies, LLC offers Advanced Insight training for FDM with Stratasys certified trainers to help customers get the most from their 3D Printers. For information please contact your CATI sales representative or call CATI at 888-308-2284.

Mark Abshire

Application Engineer, Additive Manufacturing

Computer Aided Technology

Blog

Blog